Description

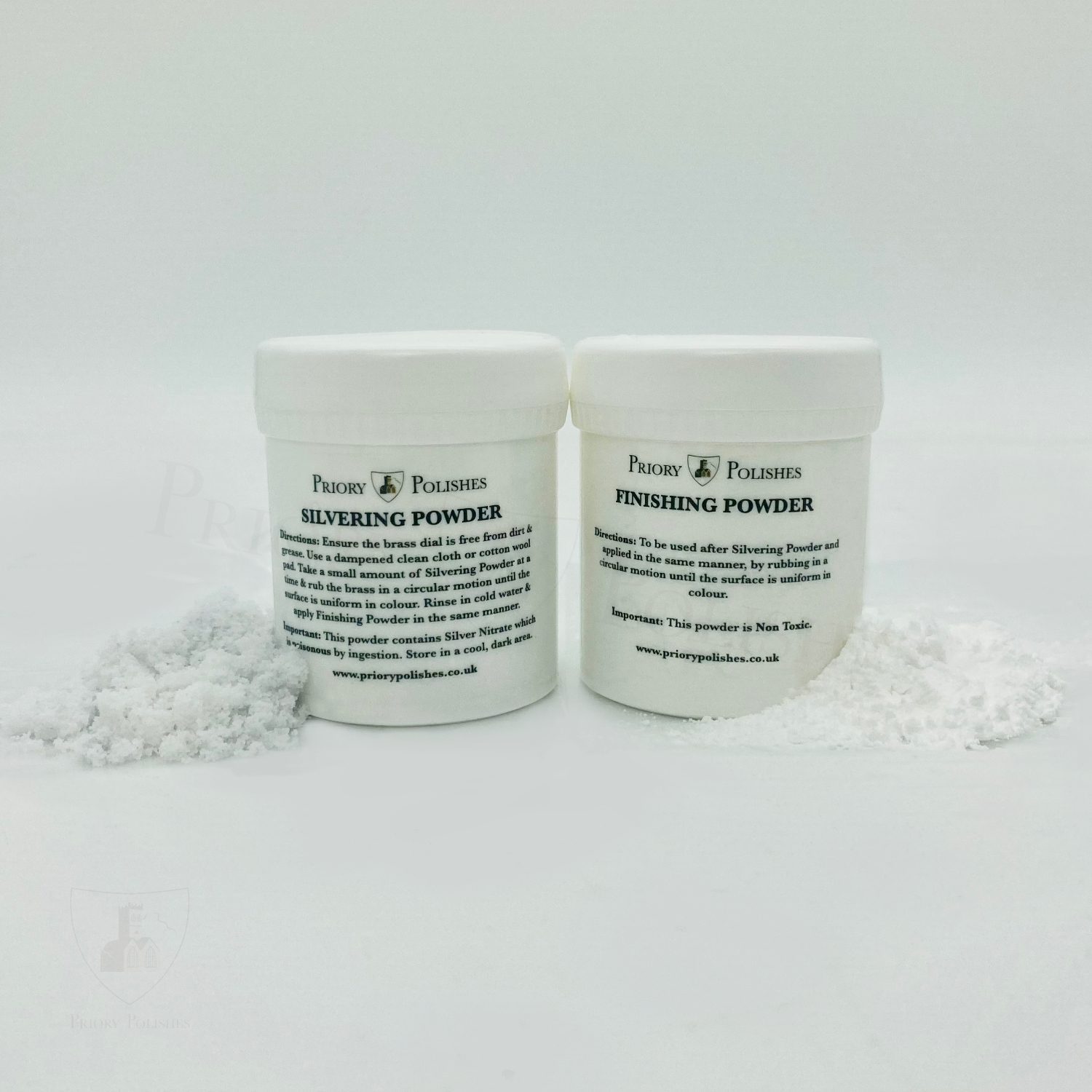

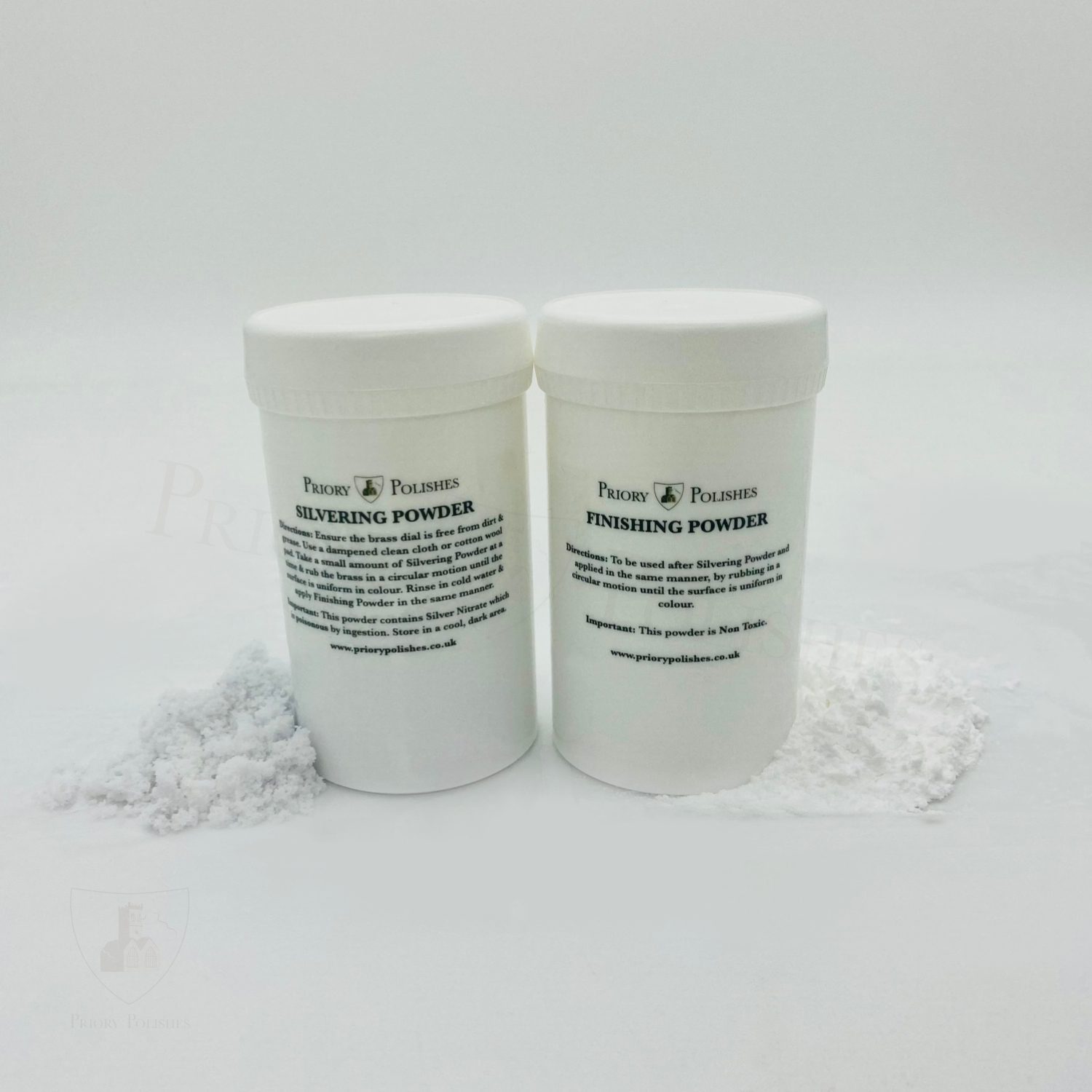

Our Antique Clock Dial Silvering Powder & Finishing Powder has been used by the Horological trade and clock restorers for many years. This has been made with an age old recipe passed down through generations of clock restorers, made from the finest quality old English silver.

How to use Dial Silvering Powder

- Brass dials that require re-silvering should be cleaned back to the brass with fine abrasive paper or very fine steel wool.

- If a ‘spun’ effect is required, put a nail in a piece of old board and rotate the dial around it while holding fine emery paper on the surface.

- Fill numerals in etched dials with black engravers wax. If the old wax is just cracked, hold the dial over a heat source to heat the wax just enough for the cracks to disappear. If the wax is missing or insufficient, add a few flakes of it to the numerals and heat gently.

- Rub the surface back down again if necessary to be level with the dial.

- Rinse under warm water and rub silvering powder into the surface with a clean cloth or tissue.

- Rinse again and apply finishing powder.

- Rinse once more to ensure there is no finishing powder left on the surface.

- For best results dry with a Hairdryer to ensure there is no moisture left on the Metal.

- When thoroughly dry apply colourless lacquer (optional).

- The lacquer should only be applied thinly to engraved dials. Dial wax will melt and run if too much lacquer is used. A soft cotton cloth or cotton wool pad can be used; a quick swipe is the usual method then leave to dry before touching or attempting to add more lacquer.

Please note

- Cleanliness is of paramount importance when silvering and almost all problems encountered are due to finger marks on the metal between cleaning and applying the powder. Silvering powder acts by chemical reaction with the metal, and if this cannot take place evenly, an uneven colouring occurs. This powder will not work on plated or lacquered dials. It will not work on aluminium. Use only on clean brass or copper Dials.

- We find that on some certain dials, they hold a lot more moisture than others. This can affect the silvering process overnight, making the brass patchy or loosing the silver effect on your dial. To resolve this, after the finishing powder process, dry quickly the front and back without spreading any grease or dirt from the back, so use different cloths. Then warm the dial quickly to ensure thorough dryness, either by hairdryer or well above a naked flame. This will ensure the cracks and stress fractures are totally dry. This will usually resolve the problem.

- Do not use on solder. Silvering powder can react badly on soft solder. The only solution is to completely remove every piece of soft solder present before use.

- Light sensitive, store in a dark place, shelf life 2-6 years if stored correctly.

For a full Clock Dial restoration, please see also see our Clock Dial Silvering Restoration Kit

Questions and Answers

I’ve successfully applied silvering and finishing powder to my 250 year old grandfather clock chapter ring. It looks fantastic but after 24 hours starts yellowing. I’ve tried applying renaissance wax, leaving it bare, drying it between finishing powder & wax, even using baking powder after finishing. It always goes yellow. Is lacquer the way to go?

This is not due to lacquer or the wax as it is happening too quickly. The two most likely causes are either the surface of the brass or waxed numerals has grease or contamination in it, where tiny blowholes or wax cracking contains impurities, or the Silvering is not taking sufficiently enough. The first is corrected by scrubbing the surface with a de-greaser like benzine or lighter fuel and then redoing it. The second is make sure the dial is wet enough when silvering. Silvering takes better on a wet dial.

Safety Data Sheets

Niall Archer (verified owner) –

simon coope (verified owner) –

Great product and so much cheaper than other makers.

Richard (verified owner) –

Good service and product. Thanks.

Russell Taylor (verified owner) –

I have used this product before and it never fails.

TERRY (verified owner) –

All good, worked reasonably well. Make sure you do a test run on a sample first.

Roy R. (verified owner) –

WOW,, it works. Just to practice I wire wool cleaned a piece of copper pipe.

After only a minute of applying the Silverering Power I was surprised how quickly the silvering showed up.

I do like to experiment so applied Finish Powder to only half of the silvered test.

DO NOT TRY THIS!!! The unfinished part tarnished within a couple of hours.

Charles Matcham (verified owner) –

kevin egner (verified owner) –

Michael Henderson (verified owner) –

Fast efficient service

Tanya (verified owner) –

Fast delivery, great product 1st time I’ve repaired a clock face easy to use great result. Thank you for your service! 😊

Ronald Dadswell (verified owner) –

Very pleased with my first attempt at silvering a chapter ring so with more confidence re-silvered the chapter ring, second hand dial and name medallion on another of my clocks. Both clocks look great.